Company Profile

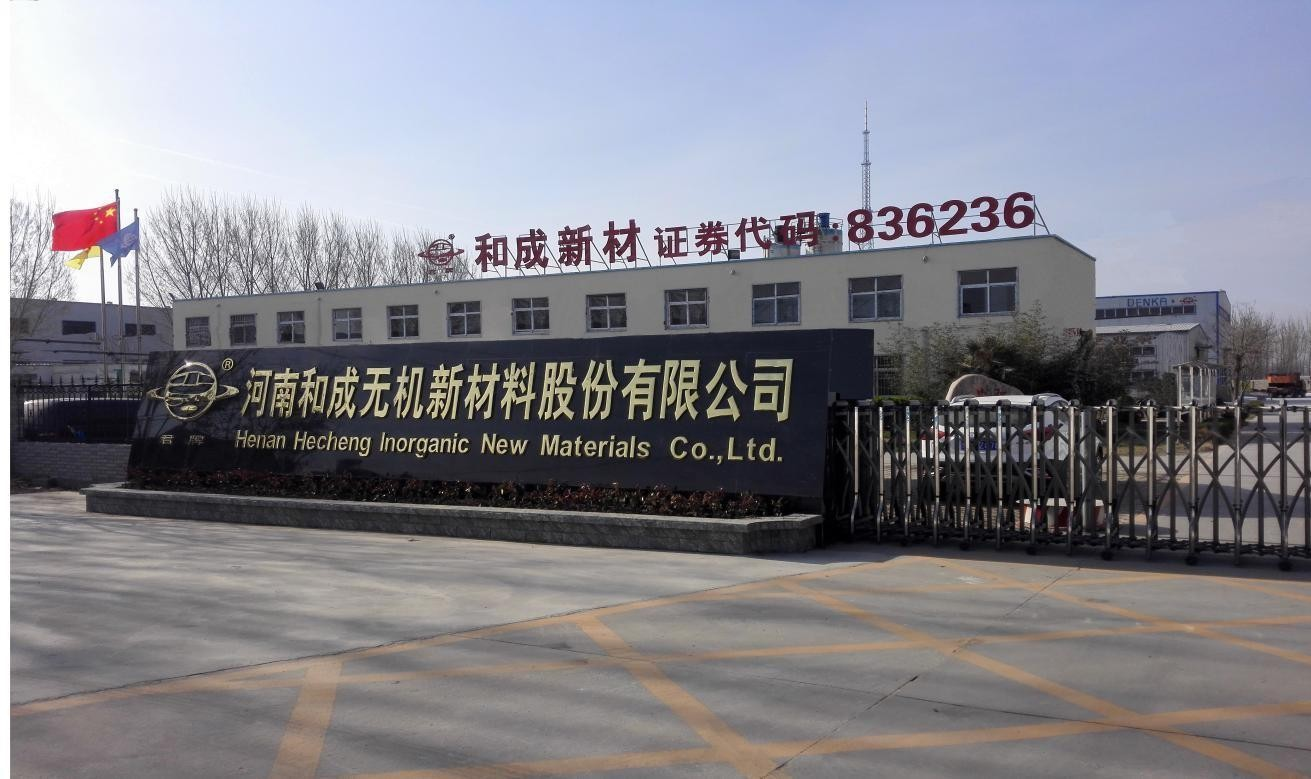

JGHECEPT Co., Ltd. is a subsidiary of Henan Hecheng Inorganic New Materials Co., Ltd. (Hecheng New Materials 836236). applied high-tech enterprises. The company has a high-level R&D team with doctoral and master students as the main body and a R&D laboratory with advanced equipment, with complete R&D capabilities from basic research, product development, production and processing to industrial application. In order to solve the problems that need to be solved urgently, such as high anode consumption, more electrolyte carbon residue and lower current efficiency caused by severe high temperature oxidation of prebaked anodes in the field of electrolytic aluminum, the company has developed a comprehensive solution for prebaked anode oxidation after years of painstaking research and development. Significantly reduce anode consumption, extend anode cycle for two days, and achieve world-leading comprehensive performance, which can create huge economic and environmental benefits for customers.

About our coating

coating method:

1. Cleaning of steel claws: use compressed air to spray and clean the anode steel claws to remove the surface dust, and use an iron shovel to remove the adhesion and residual covering material on the surface of the steel claws;

2. Use a brush to focus on the easily oxidized parts of the steel claws. After brushing for 1 time, let it dry naturally for 10-20 minutes. After the surface is initially hardened, brush a second time. The brushing amount is controlled at about 0.8-1kg/m2. Generally, it needs to be painted two to three times to meet the requirements;

3. It can also be sprayed with a high-pressure airless sprayer;

4. After painting, let it dry naturally for 24 hours, and it can be used in the groove. Note: Make sure the surface of the steel claw is dry before painting, otherwise the coating effect will be affected.

Corrosion Mechanism of Anode Steel Claw Surface

Iron oxide is a solid ionic crystal structure, and the oxide layer on the iron surface has different types of semiconducting properties, so the iron oxidation process is essentially an electrochemical reaction.

1、Oxygen or oxidizing gas diffuses to the metal surface, and forms O2- (0.5O2+2e-=O2-) by adsorption and ionization, and the metal atom M is oxidized to M2+ (M=M2++2e- )

2、O2- and M2+ diffuse in opposite directions in the formed oxide (MO)

3、M2+ and O2- react in the oxide outer layer (MO|O2 interface), the inner layer (M|MO interface), and inside the oxide layer to form oxides. Due to the larger radius of O2-, the oxide formation process is accompanied by an increase in volume. .